The pigments in fluorescent inks work by absorbing ultraviolet energy (invisible to the human eye), and transmitting it as longer waves in the visible spectrum.

To achieve the best results with fluorescent ink, consider the following guidelines:

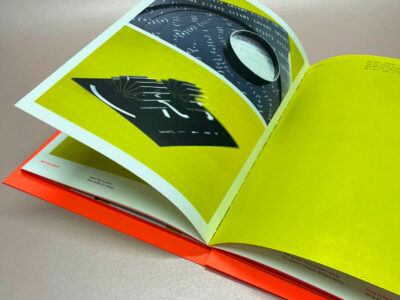

- Use uncoated UV dull papers – with low or no fluorescence such as Rives Natural White to emphasis the fluorescent inks to full effect.

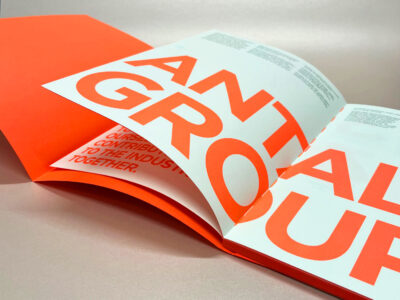

- Use fluorescent inks when printing light and bright images with large, solid areas. Fluorescent yellow and magenta provide the most impact, while blues are less effective. Fluorescent inks also have the advantage of fast drying time.

- Play with contrasts between the paper used and fluorescent ink. Printing a classic paper like Conqueror Laid or Conqueror Connoisseur with fluorescent ink will add a touch of modernity and create eye-catching communications.

- Choose where the fluorescent ink prints on the sheet, keeping other colours true such as flesh tones, by adding a fifth colour to integrate the fluorescent ink exactly where you want as a highlighted area. This will provide extra control and more impact on press.

- Consider fluorescent inks printed by the screen process where more durable, opaque, long-lasting images are required.

- Uncoated papers tend to soak up the ink, lessening the brightness of the printed images.

- One way around this problem is to substitute fluorescent process inks for traditional process inks. The printed effect is to add a luminescence to the image. The less fluorescent ink you use, though, the more subtle the radiance is.

- Avoid fluorescent ink in dark images with a lot of shadows, you can potentially lose weight and contrast.

- Do not use fluorescent ink for stationery that will be run through a laser printer or copier for fluorescent inks are not formulated to resist high heat.

- Understand the limitations of fluorescent inks; that is, they fade quickly and need to be kept out of direct sunlight, which is why they are best suited for high impact promotions with a short shelf life. In addition, they are very transparent and may require a double pass on press. Note that the amount of optical brighteners used in the substrate to be printed on will have an impact on the final result

- Do not apply coatings on fluorescent inks. Aqueous coatings can cause them to “burn out” so that they fade more quickly than when a varnish is applied. In either case, however, the coating may slightly decrease the fluorescent effect.